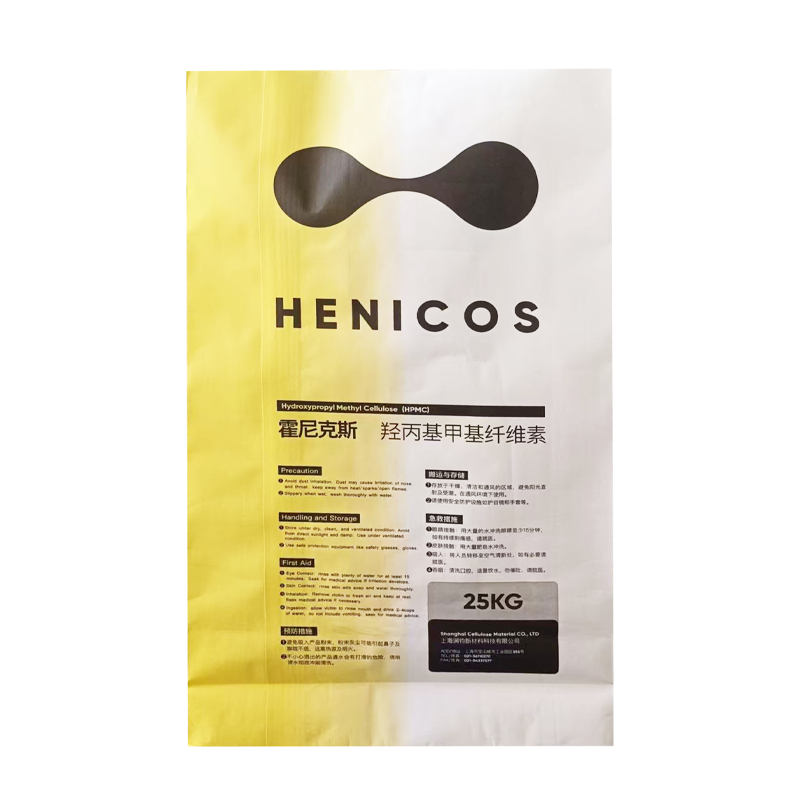

hydroxypropyl methylcellulose

CAS NO:HPK4050HPMC is a versatile pharmaceutical excipient that can be used as a thickener, dispersant, emulsifier, and film-forming agent. Using film coating and adhesive in drug tablets can significantly improve drug dissolution and enhance tablet waterproofing. It can also be used as a suspension, ophthalmic formulation, sustained-release formulation skeleton, and floating tablet.

HPMC is combined with other synthetic polymers and gelatinous drugs, which can prevent water and ethanol from being separated from clear water gelatinous drugs and improve water retention. It is also used as a thickener, emulsifier and improve rheological performance in food, cosmetics and other fields, as well as in other daily chemical industries. At present, this product has also become the main raw material for medicinal plant capsules.

Ceramic tile adhesive

Good water retention: Extend the opening time, improve construction performance, efficiency, and quality

● Improve adhesion performance and anti slip: especially for large and heavy-duty ceramic tiles, the effect is more obvious

Good working performance: lubricity and plasticity

Putty powder

● Water retention: Maximize the water content in the slurry to ensure sufficient hydration and high strength

● Anti sagging and sagging: When applying a thicker layer of putty, it can avoid production; Generate ripples

● Increase mortar production: Contains a certain proportion of HPMC; The dry mixture can be; To increase the volume of mortar

Ready mixed mortar

In pre mixed mortar, the amount of cellulose ether added is very low, but it can significantly improve the quality; The performance of wet mortar is a major factor affecting the construction performance of mortar& nbsp; Additives

The moisture retained by cellulose ether in the mortar has sufficient time to promote water retention; Continuous hydration of mud improves the adhesion between mortar and substrate. Make the mortar have; Good workability, reducing mortar shrinkage and cracking, and improving mortar quality; The output rate

Self leveling

● Smooth, non bleeding, and minimal shrinkage

Good water retention: Extend the opening time, improve construction performance, efficiency, and quality

Appearance: white or white-like powder

| project | Technical data |

| Viscosity | 33000-37000 |

| Methoxy (%) | 19.0-24.0 |

| Hydroxypropyl (%) | 4.0-12.0 |

| Gel temperature (℃) | 70.0-90.0 |

| pH (1% solution, 25 ℃ ) | 4.0-8.0 |

| Ash content (%) | 5.0 Max |

| moisture(%) | 5.0 Max |

| Particle size (%) (through 100 mesh) | 95 minimum |

Viscosity (mpa.s), 2% solution, (20+/-2) ℃, Brookfield RV, 20rpm

Please leave your contact information: